Steel Cord Scanning

About Steel Cord Scanning

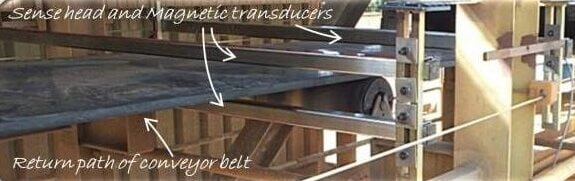

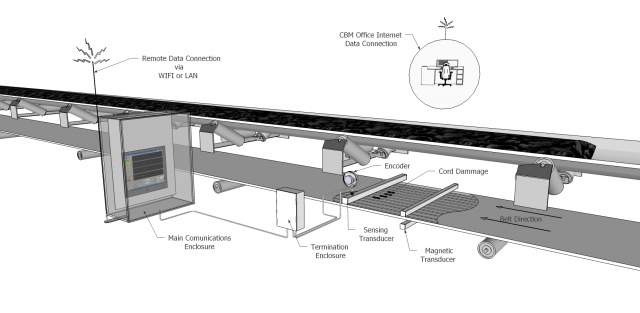

With shrinking maintenance windows and limited downtime access, CBM has developed a system to minimize interruption while scanning all forms of steel cord conveyor belting. Steel Cord Scanning via the Magnetic Flux Leakage system is designed to detect anomalies or damage within the steel cords and splices of conveyor belting, invisible to the naked eye.

When the system is operating, it locates areas of cord breakage, partially damaged, corroded cords, integrity of splices and health issues of the carcass. This information is available instantly with no conveyor downtime (depending upon the system combination Remote, Semi Remote or Full conveyor inspection), enabling full production to continue with limited or no interruption.

The data is captured via intelligent software on site or sent remotely via data connection to be inspected by engineers for anomalies. Damage can be identified immediately for notification and inspection. This is achieved through data comparison against the previously captured data.

Reports

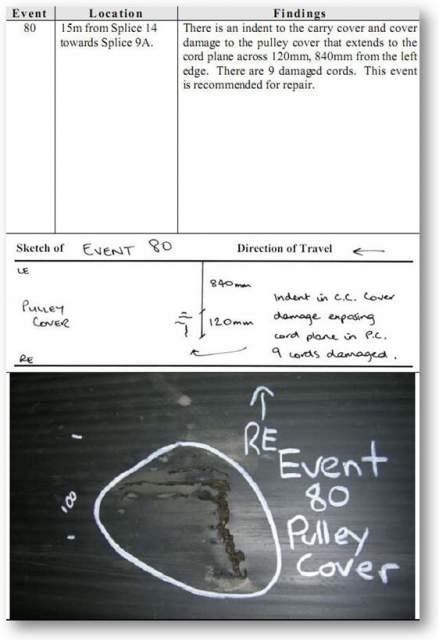

CBM engineers analyse and generate comprehensive reports using this data. The opening section of the report summarises our findings and lists recommendations in order of priority, to assist effective maintenance planning.

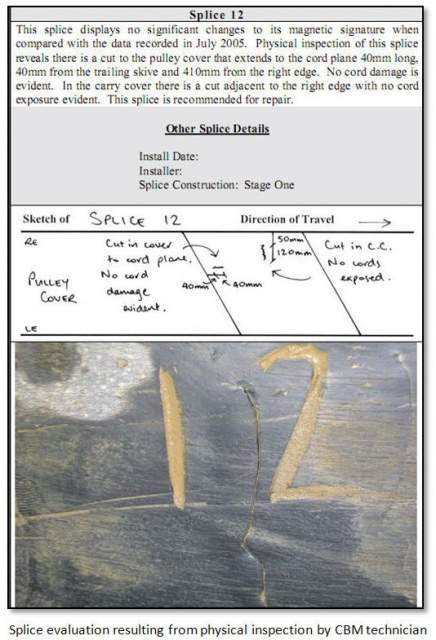

To the left is a sample page of findings from the inspection of an event, Event 80. The event's location and type of damage are described and there is both a sketch and a photograph for further reference.

Below is the cord break data for the corresponding event.

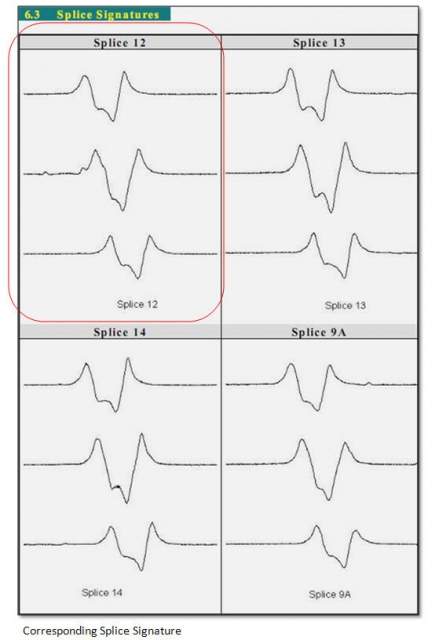

Similarly, splices are monitored. Magnetic signatures are filed and form a reference for future scans. Changes in these signatures are related to cord movement and precede splice failure.

Periodic interrogation (with a remote or semi remote installation) of the conveyor is useful in monitoring ongoing cord damage, the condition of splices (new and old) and to predict the necessity of section replacement.